Remov-Ox

What is Remov-Ox

Remov-Ox is a catalyzed Hydrazine Solution of 35%. And, it makes an effective and powerful oxygen scavenger. When the temperature inside a boiler is high it helps to perform in better way than any products for removing oxygen.

The advantages of Hydrazine has reached new heights with Vishnupriya Chemicals Pvt Ltd efforts with catalyzed Hydrazine Solution of 35% Remov-Ox Extra (Organic Catalyst) & Remov-Ox Plus (Organometallic Catalyst) in order to react with oxygen faster and also at low temperature.

The mechanical, physical and water treatment chemistry of various steam generating systems vary from one another. Remov-Ox has been designed to take care of the purpose with the right product. The important thing to note here is that both the catalyst products overcome the disadvantage of hydrazine – its slowness in reacting with oxygen at low temperature. Thus our product of Oxygen Scavengers can use Hydrazine to its maximum extent.

What is Remov-Ox

Remov-Ox is a catalyzed Hydrazine Solution of 35%. And, it makes an effective and powerful oxygen scavenger. When the temperature inside a boiler is high it helps to perform in better way than any products for removing oxygen.

The advantages of Hydrazine has reached new heights with Vishnupriya Chemicals Pvt Ltd efforts with catalyzed Hydrazine Solution of 35% Remov-Ox Extra (Organic Catalyst) & Remov-Ox Plus (Organometallic Catalyst) in order to react with oxygen faster and also at low temperature.

The mechanical, physical and water treatment chemistry of various steam generating systems vary from one another. Remov-Ox has been designed to take care of the purpose with the right product. The important thing to note here is that both the catalyst products overcome the disadvantage of hydrazine – its slowness in reacting with oxygen at low temperature. Thus our product of Oxygen Scavengers can use Hydrazine to its maximum extent.

The Oxygen Corrosion Problems – Complete Solution

The problem of Boiler Corrosion is extremely expensive. The amount of money one has to pay that arises due to repair work of metal, loss of energy and valuable time results in millions of dollars. But, one can easily prevent the problem of corrosion without incurring a lot of expense.

The corrosion that occurs in boilers is due to the dissolved oxygen that is present in the steam which is being generated along with the feed water. The solution to this problem lies in how one can prevent the oxygen from causing any damage. Majority of the systems use mechanical oxygen removal which is present in deaerators. Chemical Reducing Agents are also added to this.

The use of these agents help to combine with the dissolved oxygen and form products that are harmless. That is why they are known as the oxygen scavengers.

Oxygen in boiler water

We know that oxygen plays a role in corrosion process of boiler and metals. The dissolved gas reaches steam generator through water. Since oxygen is the damaging factor, we must remove it. In this case, we may use reducing agents and mechanical removal process.

Oxygen over metal

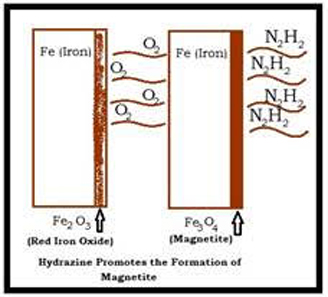

Magnetite is formed for the reaction of hot ionized water and steel. The thin magnetite layer on the surface of boiler works as the best water-resistant barrier of corrosive components and metal.

However, while there is dissolved gas (like oxygen), it will cause an impact on the barrier. The reaction of magnetite and oxygen results in an irregularity to the barrier. This impact of oxygen will form rust (chemical formula- Fe203).

Hydrazine plays a vital role in the protection of boiler steel simply by controlling the rust.

N2H4 + 6Fe2O3![]() 4Fe3O4 + 2H2O + N2

4Fe3O4 + 2H2O + N2

The main thing that is essential is some amount of hydrazine. Theatrically, magnetite is also produced due to sodium sulfite.

Na2SO4 + 3Fe2O3![]() 2Fe3O4 + Na2SO4

2Fe3O4 + Na2SO4

Various chemical trials have proved that the temperature requirement for this type of reaction is minimum 430°F. However, at about 250°F, hydrazine starts reduce the corrosion. This is also intended to create magnetite on steel at a lower temperature, like 120°F.

Corrosion Reaction

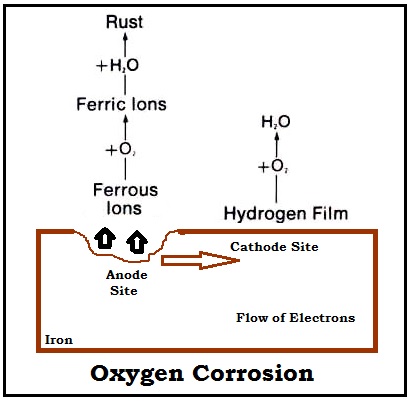

All the battery users are familiar to the electrochemical reaction, like corrosion. While the surface of any metal is not regular or consistent, it can create anodic site. Water is chosen as the electrolyte, while metal becomes electrons conductor. However, there will be no current flow through the polarized cathodic site.

When water reacts with steel, it produces hydrogen. The cathode site gets a thin film while there is no oxygen. Oxygen, in dissolved form, gets blended with hydrogen in water. Current can start flowing due to the de-polarized cathodic site. While this current of corrosion begins to flow, the ions of iron become combined with solution. We can find the presence of ions in this solution as a type of dissolved components. Finally, they get blended with the gas (oxygen) for the production of iron oxides. These oxides remain as residue on a metal, and that is what we call as rust. With the elimination of the dissolved gas, hydrogen layer restores its position and polarize cathode site.

Thus, by avoiding oxygen gas from water, we will be able to keep away from corrosion. We can add Remov –OX to boiler water for oxygen removal purpose and for corrosion problem solution.

What is an oxygen scavenger

Dissolved oxygen gets blended with reducing agents to create harmless products that we call as oxygen scavengers. They are chemicals that we use for boiler water for the elimination of oxygen, left as residue.

Hydrazine can be used as a type of oxygen scavenger. Now, for comparing various products and for dealing with various concerns, we have presented some queries and the accurate answers that help anyone to make decision. We think that it will remove your concerns and solve your queries on Remov – Ox.

Why use an oxygen scavenger

Oxygen, in dissolved form, results in corrosion at an intense pressure and temperature, found in boiler. Thus, it is essential to remove oxygen.

What are the properties of good oxygen scavengers

Fastest reaction with oxygen, volatility, absence of solids and passivating steel object- these are the properties of oxygen scavengers.

Why to use Remov-Ox

No Corrosive Solids

Remov-Ox completely miscible with water, reacts with oxygen to form nitrogen and water:

N2 H4 + O2 N2 + 2H2O

No solids are formed, and nitrogen is harmless to the system. Thus neither hydrazine itself nor its reaction products contribute dissolved solids to the system.

Compatibility with other treatment chemicals

Unlike other scavengers, Remov -Ox reaction rates are not hindered by other chemicals such as phosphates, phosphonates, chelants or sludge conditioners, that are normally used in boiler-water treatment programs. This important property assures a more thorough protection of feedwater and boiler systems. It minimizes oxygen carryover to steam and condensate lines.

Reduced iron and copper pickup

Feed water often contains dissolved or finely dispersed iron and copper particles and their oxides. Remov-Ox not only reduces rust to magnetite, but also reduces cupric oxide to its more passive form, cuprous oxide. Magnetite and cuprous oxide are dense particles, which are readily removed.In addition, considerable experience has shown Remov-Ox to be superior to sodium sulfite in controlling iron and copper pickup. Once Remov-Ox has promoted formation of a magnetite coating, boilers and other water systems remain largely free of metal oxide sludge. Remov -Ox treated boilers contain minimal metal oxide deposits when boilers are taken down for inspection and cleaning.

Control of pH

Water always includes small quantities of hydrogen and hydroxyl ions in equilibrium. With an excess of hydrogen ions present, an acidic condition exists. Iron is dissolved in the water; corrosion results. The rate of acidic attack is a function of pH. Since Remov -Ox is a base, it helps to neutralize the acid condition.

Under Pressure steam System

Our Remov – Ox solution reduces oxidation in both low and high pressure steam systems. In fact, it is the best material that can be used for protection against oxidation in super critical boilers operating at pressures up to 3500 psi.They can be used throughout the steam-generating unit.

Features of Remov-ox

| COMPATIBILITY | |||||||||||

| Product | Content of Hydrazine | Catalyst

|

Color | Type of System | Treatment |

Stainless Steel

|

Copper

|

Brass

|

Aluminium

|

||

| Remov-Ox | 35% | None | Colorless |

|

|

S | NS | NS | NS | ||

| Remov-Ox Extra | 35% | Organic | Light Pink to Light Orange | Medium Pressure (250 – 900 psig) |

|

S | NS | NS | NS | ||

| Remov-Ox Plus | 35% | Organometallic | Pink to red | Low Pressure (<250 psig) |

|

S | NS | NS | NS | ||

| S- Suitable , NS – Not Suitable | |||||||||||